PETG VS ABS PRINTING

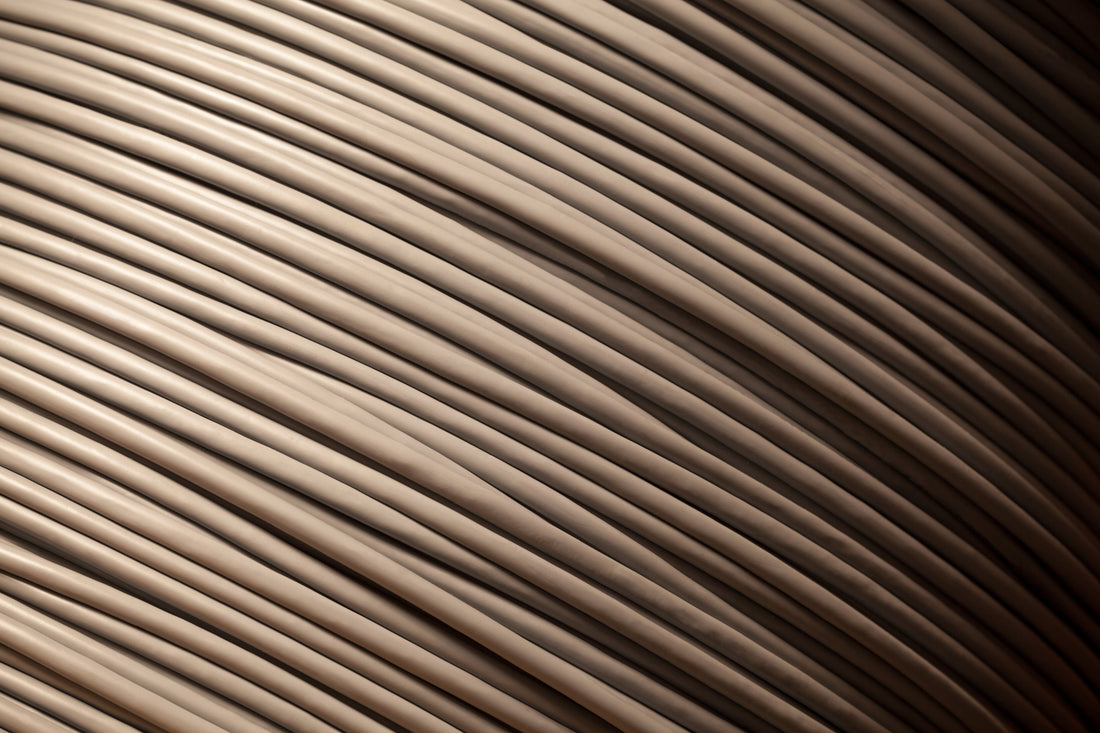

When it comes to 3D printing, choosing the right filament is crucial for achieving the desired results. Two popular options in the filament world are PETG and ABS. But which one is superior? Let's dive into the pros and cons of PETG vs ABS 3D printing and explore why PETG comes out on top.

Pros of PETG

PETG, or polyethylene terephthalate glycol-modified, is known for its strength and durability. It has a higher impact resistance than ABS, making it less prone to cracking or breaking. Additionally, PETG is more flexible, making it easier to work with when printing complex designs.

Cons of ABS

ABS, or acrylonitrile butadiene styrene, is a popular filament choice, but it does come with some drawbacks. ABS is prone to warping during the printing process, which can result in failed prints. It also emits a strong odor when heated, making it less ideal for indoor use without proper ventilation.

Why PETG is Superior

One of the main reasons why PETG is considered superior to ABS is its printing properties. PETG has a lower printing temperature compared to ABS, reducing the risk of warping and making it more suitable for a wider range of 3D printers. Additionally, PETG is more environmentally friendly than ABS, as it is recyclable and produces fewer fumes during printing.

Furthermore, PETG is transparent and resistant to UV light, making it an excellent choice for outdoor applications or projects that require transparency. Its chemical resistance also makes it a preferred option for projects that involve exposure to various chemicals.

Conclusion

While both PETG and ABS have their own set of advantages and disadvantages, PETG emerges as the superior choice for 3D printing due to its strength, flexibility, lower printing temperature, and environmental benefits. Whether you are a beginner or an experienced 3D printing enthusiast, choosing PETG as your filament of choice can lead to more successful prints and overall better results.